- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-02-18 Origin: Site

| Defect | Definition | Common Causes | |

|---|---|---|---|

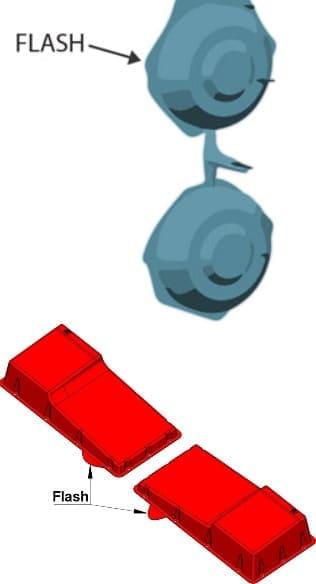

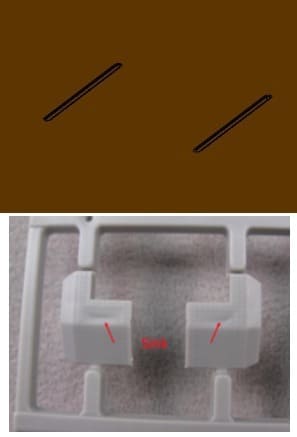

| Flash |  | Excess plastic protruding at parting lines or edges of the part. | - Insufficient clamping pressure - Excessive injection pressure - Poor mold design (e.g., damaged or worn parting surfaces) |

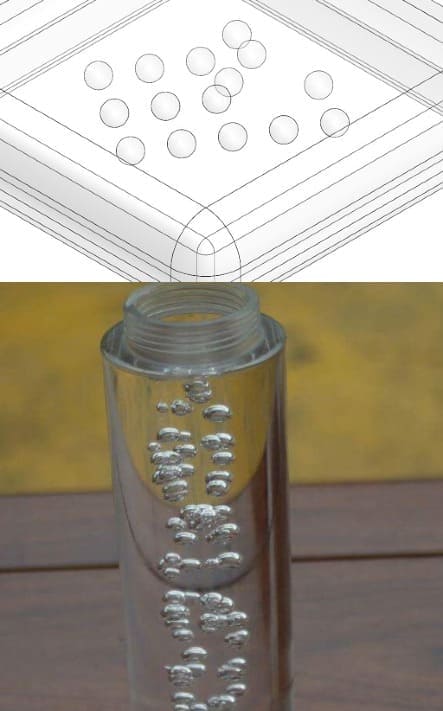

| Vacuum Voids |  | Air pockets or bubbles trapped inside the molded part, weakening structural integrity. | - Gate location in thin section causing uneven cooling - Insufficient injection or holding pressure - High melt viscosity |

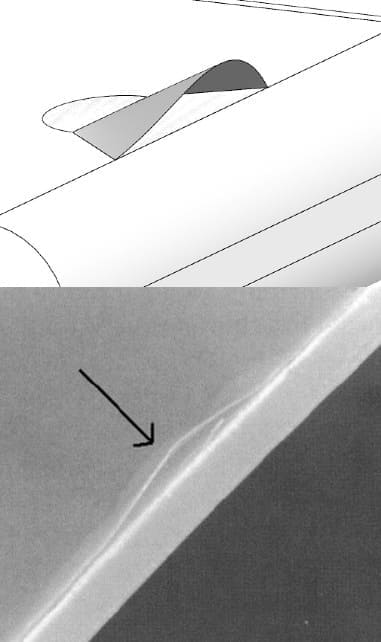

| Delamination |  | Surface layers peel or flake off; part disintegrates layer by layer. | - Contaminated plastic resin - Excessive moisture in the resin - Overuse of mold release agents |

| Short Shots |  | Incomplete filling of the mold cavity, resulting in missing sections of the part. | - Insufficient shot volume - Narrow or blocked flow channels - Low injection speed or pressure |

| Discoloration & Burnt Marks |  | Unexpected color variation or dark marks on the molded part. | - Excessive mold temperature - Low injection speed causing material degradation |

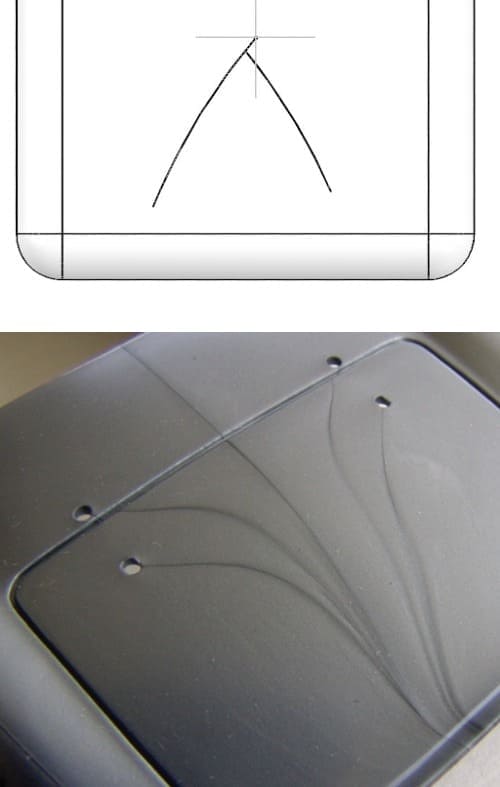

| Flow Lines |  | Wavy patterns or lines visible on the part surface following the plastic’s flow path. | - Inconsistent melt flow speed or direction - Variation in wall thickness - Suboptimal injection speed and pressure |

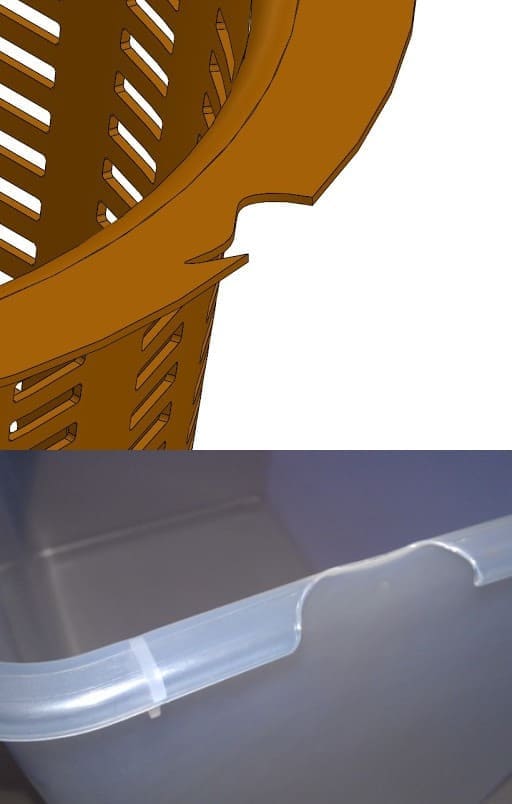

| Sink Marks |  | Depressions or dents on thicker areas of the part due to internal shrinkage. | - Inadequate or uneven cooling in thick sections - Insufficient packing/holding pressure - Improper part design (non-uniform wall thickness) |

Next page we will tell about how to solve these defeces, welcome to contact Shine (Email: shine@swymould.com or Phone: +86 15757668880), thank you!